The step-by-step assembly process allows you to understand the various modules and parts of the printer in more detail. Have fun with funny DIY sessions, enjoy the assembly process, and savor the feeling of achieving a successful challenge.

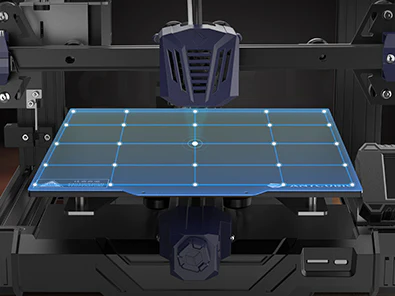

Equipped with the self-developed Anycubic LeviQ automatic leveling system. It is easy to operate, very user-friendly for new users, and entry-level users can easily level and achieve printing with just one touch, thanks to the 25-point precise detection algorithm.

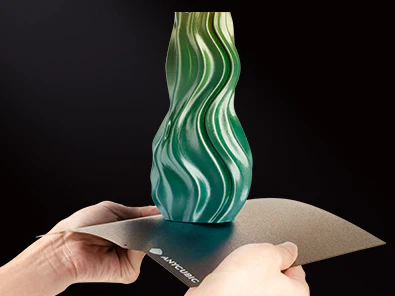

The print platform is made of wear-resistant, drop-resistant, and bend-resistant spring steel. After printing is completed, models can be easily removed by bending. The magnetic design is easy to install and allows for ultra-easy model removal.

With a typical print speed of up to 60 mm/s and a maximum print speed of 100 mm/s to revitalize creativity. *Based on Anycubic Lab test results, for reference only.

Designed with a separate Bowden extruder. When the extruder and hot end are separated, the hot end is lighter, encounters less inertia during movement, and provides higher print speed.

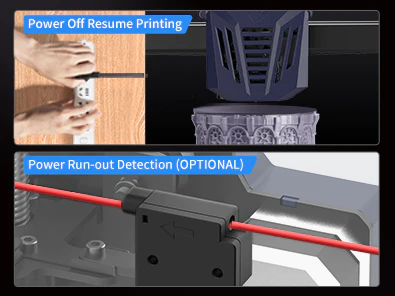

Continue printing after a power outage and filament run-out detection (optional) prevent printing errors caused by unexpected power/material interruptions, effectively reducing waste of resources and time.

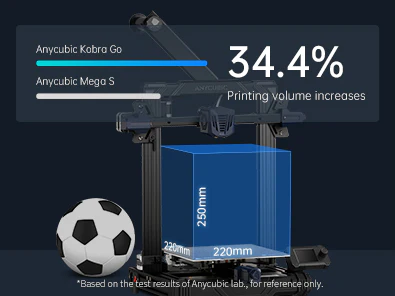

Compared to its predecessor, the Anycubic Mega S, the print volume has increased by 34.4% to reach 12.1 liters. The print size is 250 x 220 x 220 mm, equivalent to the size of 5 standard soccer balls.

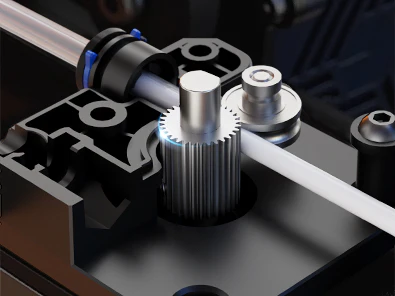

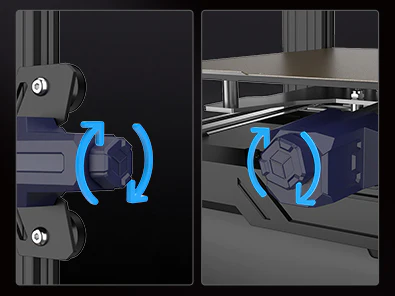

Compared to using a screwdriver, the knob-designed XY axis belt tensioner makes it easier to adjust belt tension. It is more convenient without tools and can be operated by hand alone.