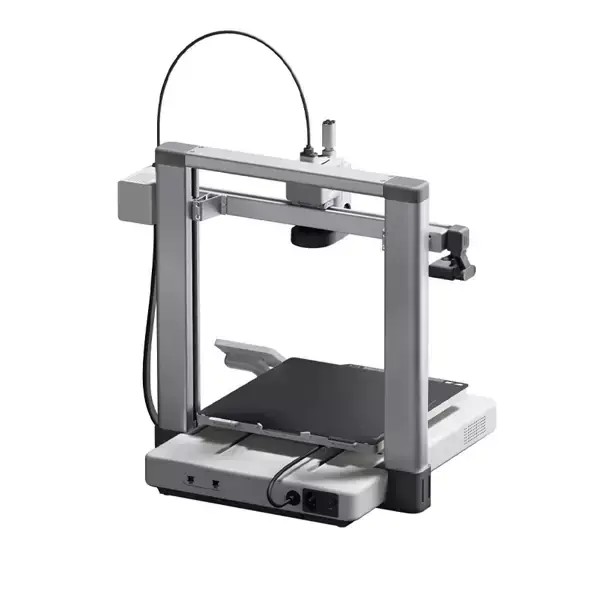

Bambu Lab A1 3D Printer introduces a fresh perspective to the world of 3D printing. Incorporating many cutting-edge technological features, this printer aims to exceed user expectations by combining innovation and ease of use.

First and foremost, through intelligent flow control, it enhances the printing process by actively compensating for flow speed using data from pressure measurements. Additionally, with its fully automatic calibration feature, the printer itself performs various calibrations autonomously, saving time for users and enhancing print quality.

By minimizing motor noise, it provides a quiet and smooth working environment, thereby improving the user experience. It increases productivity by providing high-speed and high-quality prints through the CoreXY motion control system.

Moreover, it enhances user flexibility by offering remote control and monitoring capabilities via Bambu Studio or Bambu Handy. Additionally, with the built-in camera, users can easily track the printing process by recording timelapse videos.

Equipped with durable materials such as a large build volume, steel chassis, fully metal hotend, and steel extruder gears, this printer promises long-lasting and reliable performance.

The Bambu Lab A1 3D Printer is a premium 3D printing solution designed to meet and exceed the needs and expectations of users.

Features:

Active Flow Speed Compensation: The Bambu Lab A1 3D Printer revolutionizes flow control in 3D printing. It utilizes a high-resolution, high-frequency vortex current sensor to measure pressure in the nozzle. Our algorithm actively compensates the flow speed based on accurate readings for extrusion.

Fully Automatic Calibration: The Bambu Lab A1 3D Printer performs various calibrations autonomously. It meticulously calibrates Z-offset, bed leveling, vibration resonance, and nozzle pressure automatically for every printing job.

Active Motor Noise Reduction: The Bambu Lab A1 3D Printer can calibrate parameters to match small individual differences between each drive motor. This compensates for unwanted harshness in motor noise.

CoreXY Speed and Quality with Bed Suspension: Utilizing advanced motion control system features like fully metal rails, a rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and most importantly, a CoreXY motion control system that utilizes these features to print a quality bed in 14 minutes and follow all the speed bed rules directly. without using special filaments.

Synchronization with Bambu Studio and Bambu Handy: Control and monitor your printer remotely through Bambu Studio or Bambu Handy. You can also record timelapse videos with the built-in camera.

Technical Specifications:

Build Volume: 256x256x256 mm³

Chassis: Steel

Hotend: Fully Metal

Extruder Gears: Steel

Nozzle: Stainless Steel

Maximum Hotend Temperature: 300 ℃

Nozzle Diameter (Included): 0.4 mm

Filament Cutter: Yes

Filament Diameter: 1.75 mm

Build Plate: Bamboo Textured PEI Plate

Maximum Build Plate Temperature: 100 ℃

Maximum Head Speed: 500 mm/s

Maximum Head Acceleration: 10m/s²

Control Board Fan: Closed Loop Control

Chamber Temperature Regulator Fan: Closed Loop Control

Auxiliary Part Cooling Fan: Closed Loop Control

Air Filter: Activated Carbon Filter

Supported Filaments: Ideal: PLA, PETG, TPU, PVA, PET, ABS, ASA

Room Monitoring Camera: Low-Speed Camera 1080P (Supports Timelapse)

Filament Sensor: Available

Filament Odometry: Available

Power Loss Recovery: Available

Product Size: 385x410x430 mm³

Net Weight: 8.3 kg

Package Size: 546x536x420 mm³

Power Requirements: 100-240 VAC, 50/60 Hz, 1000 W @220 V, 350 W @110V

Package Contents:

1 x Bambu Lab A1 3D Printer

First and foremost, through intelligent flow control, it enhances the printing process by actively compensating for flow speed using data from pressure measurements. Additionally, with its fully automatic calibration feature, the printer itself performs various calibrations autonomously, saving time for users and enhancing print quality.

By minimizing motor noise, it provides a quiet and smooth working environment, thereby improving the user experience. It increases productivity by providing high-speed and high-quality prints through the CoreXY motion control system.

Moreover, it enhances user flexibility by offering remote control and monitoring capabilities via Bambu Studio or Bambu Handy. Additionally, with the built-in camera, users can easily track the printing process by recording timelapse videos.

Equipped with durable materials such as a large build volume, steel chassis, fully metal hotend, and steel extruder gears, this printer promises long-lasting and reliable performance.

The Bambu Lab A1 3D Printer is a premium 3D printing solution designed to meet and exceed the needs and expectations of users.

Features:

Active Flow Speed Compensation: The Bambu Lab A1 3D Printer revolutionizes flow control in 3D printing. It utilizes a high-resolution, high-frequency vortex current sensor to measure pressure in the nozzle. Our algorithm actively compensates the flow speed based on accurate readings for extrusion.

Fully Automatic Calibration: The Bambu Lab A1 3D Printer performs various calibrations autonomously. It meticulously calibrates Z-offset, bed leveling, vibration resonance, and nozzle pressure automatically for every printing job.

Active Motor Noise Reduction: The Bambu Lab A1 3D Printer can calibrate parameters to match small individual differences between each drive motor. This compensates for unwanted harshness in motor noise.

CoreXY Speed and Quality with Bed Suspension: Utilizing advanced motion control system features like fully metal rails, a rigid frame, nozzle pressure sensor, accelerometers, powerful MCU, and most importantly, a CoreXY motion control system that utilizes these features to print a quality bed in 14 minutes and follow all the speed bed rules directly. without using special filaments.

Synchronization with Bambu Studio and Bambu Handy: Control and monitor your printer remotely through Bambu Studio or Bambu Handy. You can also record timelapse videos with the built-in camera.

Technical Specifications:

Build Volume: 256x256x256 mm³

Chassis: Steel

Hotend: Fully Metal

Extruder Gears: Steel

Nozzle: Stainless Steel

Maximum Hotend Temperature: 300 ℃

Nozzle Diameter (Included): 0.4 mm

Filament Cutter: Yes

Filament Diameter: 1.75 mm

Build Plate: Bamboo Textured PEI Plate

Maximum Build Plate Temperature: 100 ℃

Maximum Head Speed: 500 mm/s

Maximum Head Acceleration: 10m/s²

Control Board Fan: Closed Loop Control

Chamber Temperature Regulator Fan: Closed Loop Control

Auxiliary Part Cooling Fan: Closed Loop Control

Air Filter: Activated Carbon Filter

Supported Filaments: Ideal: PLA, PETG, TPU, PVA, PET, ABS, ASA

Room Monitoring Camera: Low-Speed Camera 1080P (Supports Timelapse)

Filament Sensor: Available

Filament Odometry: Available

Power Loss Recovery: Available

Product Size: 385x410x430 mm³

Net Weight: 8.3 kg

Package Size: 546x536x420 mm³

Power Requirements: 100-240 VAC, 50/60 Hz, 1000 W @220 V, 350 W @110V

Package Contents:

1 x Bambu Lab A1 3D Printer

Your Last Viewed